Washing efficiency

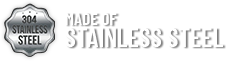

Fully manufactured in AISI-304 stainless steel, state-of-the-art technology, and custom design of industrial washer-dryers for containers, fruit and vegetables for cleaning and hygiene in the production processes of any factory. Appropriate monitoring of traceability of your products so that they arrive in perfect conditions of quality and safety to the final consumer.

Fruit and vegetable washer-dryer

Ensures quality

Your fruit and vegetables guaranteed clean and fresh. Ensure food quality with a water-based wash, eliminating germs and maintaining the original flavour of the product.

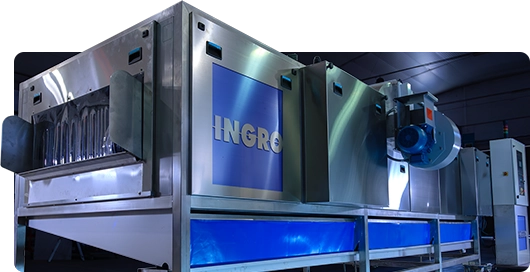

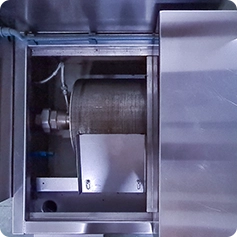

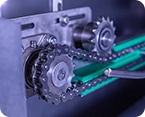

Includes two washing systems. For loose products with an oval or spherical shape, the cleaning process is carried out using rollers that rotate the fruit or vegetable on itself, applying brushing with the care to keep it in perfect condition until the final wash. Product on the vine or boxed are sprayed with pressurised water while conveyed by a modular belt.

Saves on labour and achieves excellent results.

Length according to production line

For product in boxes, loose or on the vine

Custom performance

PLC and touchscreen control

Environmentally friendly

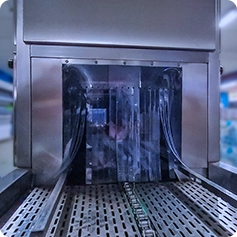

Washing machine for boxes and containers

Removes dirt and pathogens

Its special polypropylene nozzle washing system eliminates dirt and pathogens by performing a complete cleaning. You can add containers and boxes manually or automatically. View and modify any parameter: washing frequency, speed, temperature, consumption, etc.

Various types of packaging

Ideal for different types of packaging and dirt levels. It incorporates an automatic detergent dosing and water purification system thanks to its self-cleaning rotary filter, allowing for reuse.

Standard length: 3m / 5m

For different sizes of boxes and containers

Yield: 500 to 1000 boxes/h

PLC and touchscreen control

Efficient and environmentally friendly

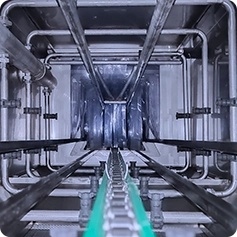

Drying option

Includes a drying option in the box and container washing models to dry the container surfaces thoroughly and eliminate excess water.

High-pressure air is channelled through air blades to effectively reach the product, removing every drop of water generated during washing and ensuring every part of the container is dry. The drying option provides excellent flexibility in managing the settings, whether automatically or manually. Additionally, it can be directly connected to a central collector to remove empty containers.

Your success is our goal

Robustness

At Ingro Maquinaria, part of the Almafrut Group, we have been innovating for more than two decades.

Maintenance

Comprehensive support with on-site visits to your company to expedite the solution.

Reliability

The most advanced technology with the best team of professionals at your service.

Comprehensive solution

Technical support, development, installation, and after-sales service for our machinery.

You are our customer. We reach every corner of the country and the globe, providing effective solutions to companies in the fruit and vegetable, food and packaging sectors.

Development of customised projects

Rigorous working method

Highly specialised technical team

Timely delivery

Maximum quality in all components

Support from staff who are always willing to help